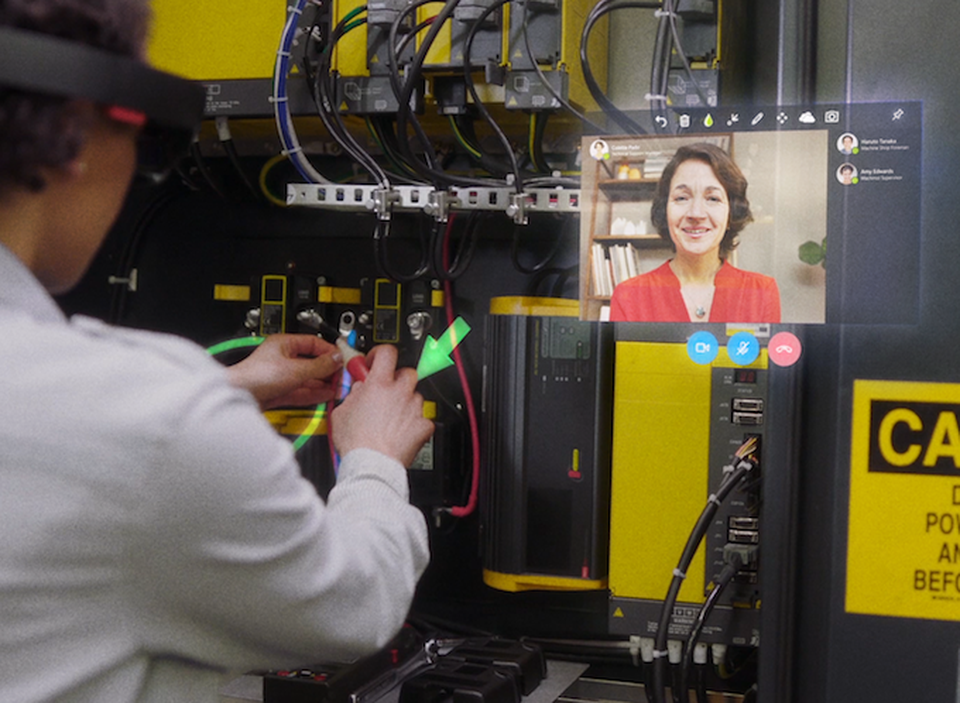

Luxury automaker Mercedes-Benz has joined the growing list of automakers adopting augmented reality to provide an assist to its manufacturing operations, in this case, via the Microsoft HoloLens.

The company employs more than 100 HoloLens devices in its Mercedes-Benz Global Training program, where about 450 management, product, branding, and sales employees have access to the devices.

Through the HoloLens, participants are able to examine 3D models of vehicles, view the car’s internal parts, and understand its complex systems in more detail. The device also gives them an opportunity to learn how to generally apply AR technology to their various job roles.

Communication and media studio IJsfontein showed off one of the training experiences via video. Built in collaboration Wegesrand Expert Network and Mercedes-Benz Global Training, the app enables customers to view the various features of a Mercedes-Benz A-Class in augmented reality.

„One of our participants, a sales professional, told us that HoloLens would allow him to need only one car in his showroom,“ said Ralf Krieger, a training coach at Mercedes-Benz Global Training, in a Microsoft blog post. „He envisioned using HoloLens in a way that his customers could touch the physical car, but also see, through mixed reality, how that same model would look if they wanted different components.“

- Don’t Miss: Microsoft Unveils Remote Assist & Layout, New HoloLens Apps Aimed at Workforce Productivity

In the post, Microsoft illustrates how adaptable AR can be across audiences. For example, Krieger’s colleague, Walter Bauch, only began using a smartphone two years ago. Today, he uses the HoloLens to train his co-workers.

„People come in and hear my story. They realize: Here is this guy who never used a smartphone until two years ago and now he is using HoloLens in his job. People do not believe it,“ said Bauch. „This is the signal we send out to our visitors: It’s not the age of the user that matters. This device is for people of all ages. Our oldest participant was 89. He attended with his 60-year-old son. I will never forget what he told us: ‚I wish I’d had this technology when I was young and handsome.'“

While Mercedes-Benz is focusing on training with the HoloLens (and showroom experiences not unlike those used by Volvo), other automakers like Ford are using the device to improve engineering design processes while Renault Trucks has been using the technology to guide factory workers through complex processes. Elsewhere, Porsche is using Atheer AiR to assist mechanics with repairs.

Though the implementations across brands may vary, and mainstream consumers are still largely unfamiliar with devices like the HoloLens, the increasing adoption of augmented reality among automakers and other manufacturing industries demonstrates that businesses are already finding value and utility in the technology today, even if the rest of the public takes a few years to catch up.

Quelle:

Image by IJsfontein/YouTube

http://www.virtualrealitypulse.com/training/?open-article-id=8691465&article-title=mercedes-benz-shifts-to-hololens-for-employee-training&blog-domain=reality.news&blog-title=next-reality-ar

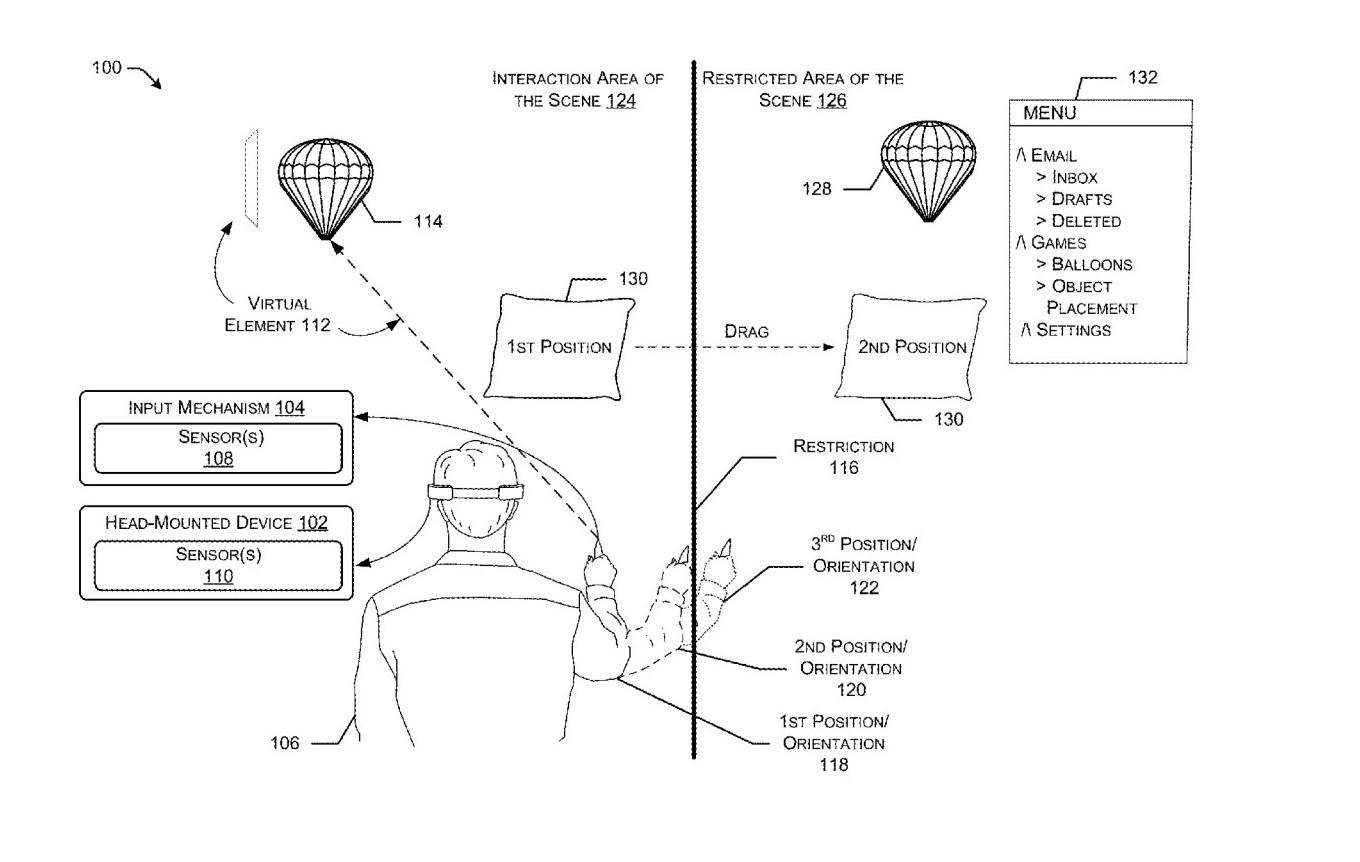

Die Skizze zeigt eine Person mit eingeschränktem Bewegungsspielraum. Trotz dieser Einschränkung können durch die Technologie Gegenstände im virtuellen Raum so platziert werden, das man problemlos mit ihnen interagieren kann.

Die Skizze zeigt eine Person mit eingeschränktem Bewegungsspielraum. Trotz dieser Einschränkung können durch die Technologie Gegenstände im virtuellen Raum so platziert werden, das man problemlos mit ihnen interagieren kann. Nichtsdestotrotz ist das Bild eines körperlich behinderten Menschen, der im virtuellen Raum eine völlig neue Freiheit erlangt, in meinen Augen das stärkste Motiv, um das Patent zu beschreiben. Und passend, denn heute ist Tage der Inklusion.

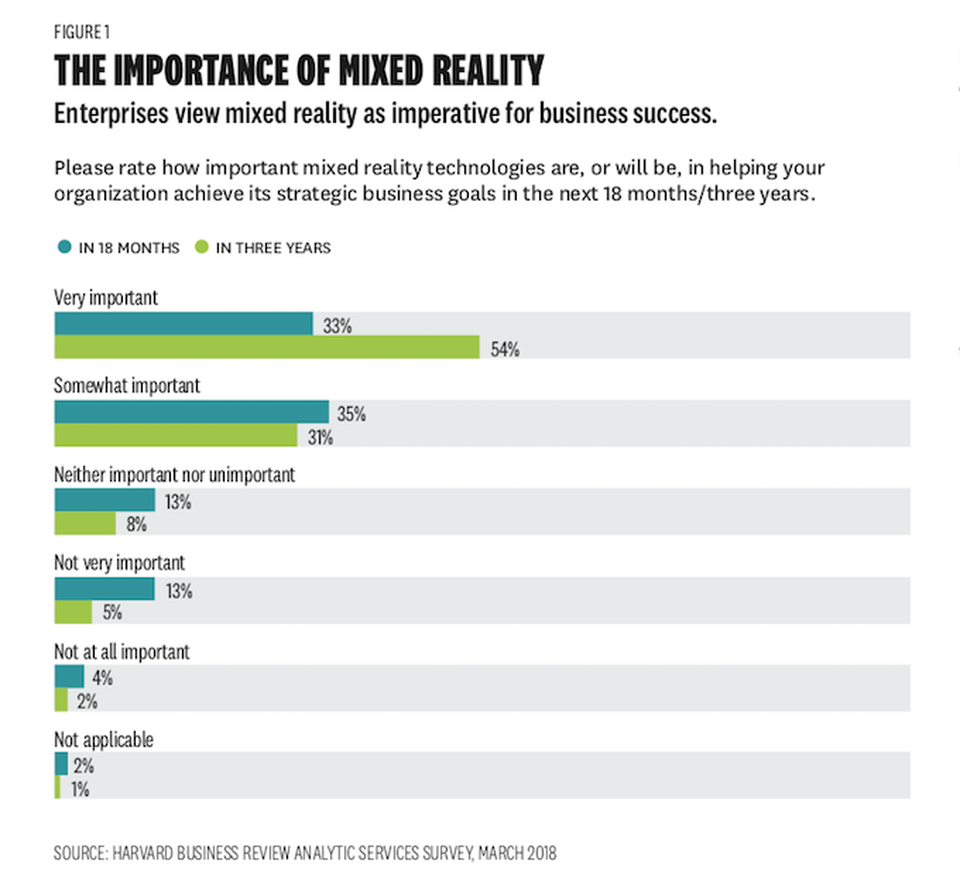

Nichtsdestotrotz ist das Bild eines körperlich behinderten Menschen, der im virtuellen Raum eine völlig neue Freiheit erlangt, in meinen Augen das stärkste Motiv, um das Patent zu beschreiben. Und passend, denn heute ist Tage der Inklusion. In a wide-ranging conversation with Bardeen I asked her to explain Microsoft’s motivation for commissioning the report,

In a wide-ranging conversation with Bardeen I asked her to explain Microsoft’s motivation for commissioning the report,  One of the key opportunities identified by the survey concerns what Microsoft calls “Firstline Workers”, who makeup 80 percent of the workforce but often have limited access to relevant, contextual information due to the on-the-field or on-the-floor nature of their jobs. These workers are typically on the front lines of any business workflow: behind the counters, in the clinics, traveling between customers for field service, or on the factory floor. “Several of Microsoft’s commercial customers are already empowering their Firstline Workers with mixed-reality solutions that enable remote assistance, spatial planning, environmentally contextual data, and much more,” Bardeen told me. With the

One of the key opportunities identified by the survey concerns what Microsoft calls “Firstline Workers”, who makeup 80 percent of the workforce but often have limited access to relevant, contextual information due to the on-the-field or on-the-floor nature of their jobs. These workers are typically on the front lines of any business workflow: behind the counters, in the clinics, traveling between customers for field service, or on the factory floor. “Several of Microsoft’s commercial customers are already empowering their Firstline Workers with mixed-reality solutions that enable remote assistance, spatial planning, environmentally contextual data, and much more,” Bardeen told me. With the  In order to fuel further interest from developers and businesses Microsoft is sharing use case videos, blog posts, and making presentations conferences like

In order to fuel further interest from developers and businesses Microsoft is sharing use case videos, blog posts, and making presentations conferences like  Select Microsoft stores throughout the US are demoing the HoloLens by appointment.

Select Microsoft stores throughout the US are demoing the HoloLens by appointment.