The Challenge

Aircraft Readiness is a number one priority for both military and commercial aviation. Maintenance task troubleshooting and execution time and error rates are significant aircraft readiness degraders.

An additional stressor occurs when an organization must extend the life of its equipment; in some cases, 10-20 years beyond an aircraft’s expected life. This puts unanticipated strain on systems and structures, resulting in excessive down time for repairs. In some cases, 40%-50% of the inventory of a platform are unusable at any point in time.

Maintenance errors are a leading cause of inventory down time. For example, a mistake made on a fuel cell replacement can result in an aircraft being down for 6 months or longer, driving enormous cost, and risk to global safety. Even the best training tools can reduce errors down to 75%, but today’s economic and global situation require something better. Aerospace needs a training solution that can be used on the job, and produce zero errors.

AVATAR Partners was approached by a community of maintainers to address a common issue in one fixed wing aircraft, which was a Wiring issue (specifically, the Left Main Landing Gear Planing Link Proximity Switch Fail).

The problem was complex:

• The task required 3 non-integrated sources (IETM, Wire Illuminator, Schematic)

• Tasks to gain access to test points was not identified

• Wire Illuminator visuals did not include installed components

• Poor wire illuminator visuals cause confusion in wiring orientation

• Visuals did not show necessary connection points

• Time intensive testing and strict time constraints

The Solution

To address the issue, AVATAR Partners used a standard Criticality, Difficulty, Frequency (CDF) analysis model to identify the optimal training solution; clearly, an advanced solution that would allow the maintainer to get assistance without leaving the job itself, was critical.

AVATAR researched all training technologies available, and designed a Mixed Reality solution, which combines both Augmented Reality and Virtual Reality. At the time, most Augmented Reality solutions relied on the use of markers or codes to identify the object. AVATAR joined the Vuforia VIP program and developed the Augmented Reality Maintenance Aid (ARMA), and worked with the vendor to develop an advanced object tracking system that would lock on target based on the shape of the object itself (using CAD data). Furthermore, most AR solutions had the issue of drift or jitter when dealing with a large object, such as an aircraft. The maintainer must be able to walk around the aircraft without any shift or jitter; if not, the maintainer loses all confidence in the solution. AVATAR Partners was able to eliminate shift and jitter entirely, regardless of the object size.

The Result

ARMA is a Mixed Reality industrial-grade training and job performance aid, useable under unpredictable environmental conditions. The results are as follows:

- ARMA Reduces Time to Troubleshoot by 75%

- With lock-on Object Tracking and elimination of drift/jitter, ARMA gains 100% confidence of the maintainer

- Because ARMA is configurable, it can be designed to support any aircraft platform type

- ARMA is scalable, allowing the maintainer to train in any environment, with or without the aircraft, or with a scaled down model, through the use of object tracking

- ARMA is “Two for the price of One” – can be used in both training and on the job

- ARMA is a hardware-agnostic and integrates with flight-ready glasses today

- Increases the number of Ready Aircraft

- Modular, extensible, integrates with any backend system, and allows multi-user collaboration

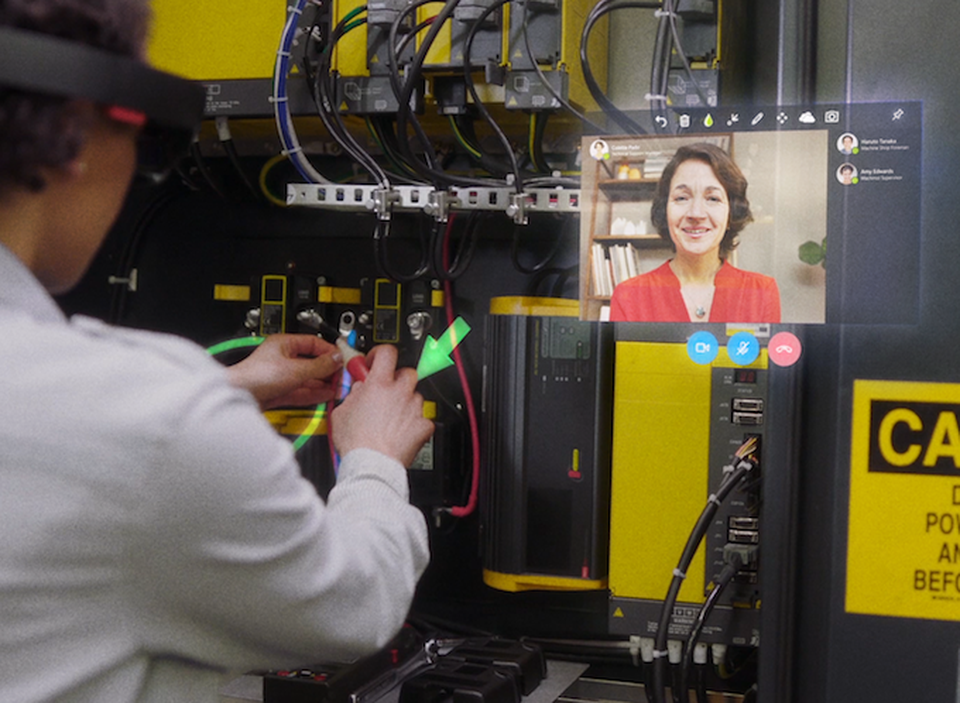

- ARMA offers remote assistance which allows remote Subject Matter Experts to view, guide and record users remotely through steps and processes.

The AVATAR Team has developed other MR solutions that reduce cost and errors throughout the manufacturing process. Another example is the assembly of large, complex ships, where our team developed a Mixed Reality solution that Quality Assurance Time on Task by 90% while Eliminating Errors to Zero. Our ever-present objective, Simplifying Complex Systems™, is a success story that keeps growing.

Quelle:

Marlo Brooke, President and CEO, Avatar Partners

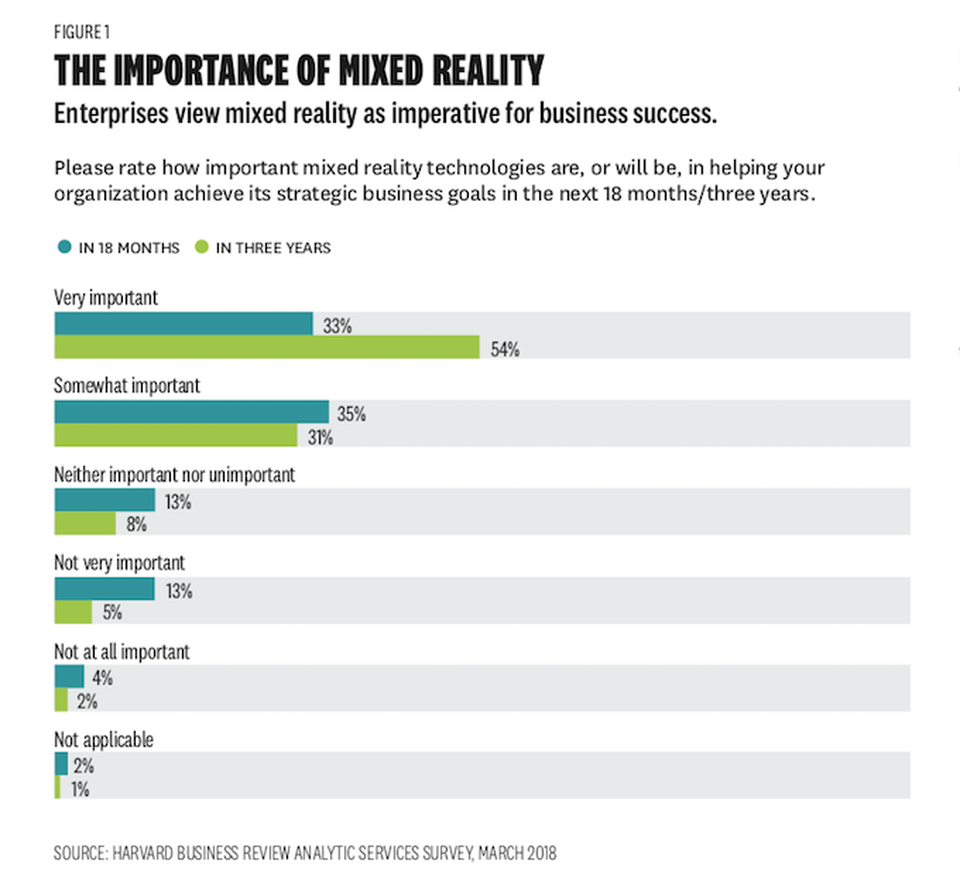

In a wide-ranging conversation with Bardeen I asked her to explain Microsoft’s motivation for commissioning the report,

In a wide-ranging conversation with Bardeen I asked her to explain Microsoft’s motivation for commissioning the report,  One of the key opportunities identified by the survey concerns what Microsoft calls “Firstline Workers”, who makeup 80 percent of the workforce but often have limited access to relevant, contextual information due to the on-the-field or on-the-floor nature of their jobs. These workers are typically on the front lines of any business workflow: behind the counters, in the clinics, traveling between customers for field service, or on the factory floor. “Several of Microsoft’s commercial customers are already empowering their Firstline Workers with mixed-reality solutions that enable remote assistance, spatial planning, environmentally contextual data, and much more,” Bardeen told me. With the

One of the key opportunities identified by the survey concerns what Microsoft calls “Firstline Workers”, who makeup 80 percent of the workforce but often have limited access to relevant, contextual information due to the on-the-field or on-the-floor nature of their jobs. These workers are typically on the front lines of any business workflow: behind the counters, in the clinics, traveling between customers for field service, or on the factory floor. “Several of Microsoft’s commercial customers are already empowering their Firstline Workers with mixed-reality solutions that enable remote assistance, spatial planning, environmentally contextual data, and much more,” Bardeen told me. With the  In order to fuel further interest from developers and businesses Microsoft is sharing use case videos, blog posts, and making presentations conferences like

In order to fuel further interest from developers and businesses Microsoft is sharing use case videos, blog posts, and making presentations conferences like  Select Microsoft stores throughout the US are demoing the HoloLens by appointment.

Select Microsoft stores throughout the US are demoing the HoloLens by appointment.