BMW Group is leading the Industry 4.0 revolution, harnessing virtual reality and advanced robotics to set new benchmarks for efficiency and innovation

A new paradigm known as Industry 4.0 is reshaping how products are designed, produced and delivered. This fourth industrial revolution, characterised by the integration of digital technologies, artificial intelligence and advanced robotics into manufacturing processes, promises to create smarter, more efficient and more responsive production systems.

At the heart of Industry 4.0 are technologies such as the Internet of Things (IoT), AI, cloud computing and advanced robotics. These technologies work in concert to create “smart factories” where machines, systems, and humans communicate and collaborate in real-time, optimising production processes and driving unprecedented levels of efficiency.

Embracing cutting-edge Industry 4.0 technologies to revolutionise its manufacturing processes. BMW is showcasing how the automotive industry can leverage advanced technologies from virtual reality simulations to trials with humanoid robots to enhance efficiency, improve worker safety and prepare for the future of manufacturing.

An employee explores the future factory using cutting-edge virtual reality tools

Virtual Reality: Stepping into the future factory

At BMW Group Plant Regensburg, this future is already here – at least in virtual form. As the plant prepares for the production of the NEUE KLASSE, BMW’s next model generation set to launch in the second half of the decade, virtual reality (VR) is playing a crucial role in planning and preparation.

Plant Director Armin Ebner explains: “With the NEUE KLASSE, which is based on an entirely new vehicle architecture, our goal as a company is to set new standards for digitalisation, electrification and circularity. Today, many years before the official launch of series production, virtual planning of the new production lines is already well underway.”

The plant is utilising “3D human simulation” for the first time company-wide in a pilot project implemented in vehicle assembly, allowing BMW to not only map future manufacturing structures virtually in a digital twin but also simulate the employees who will work on the assembly lines.

According to Sebastian Moser, an innovation and digitalisation specialist for the Regensburg production system: „This allows us to not only map future manufacturing structures virtually in a digital twin, but also simulate the employees who will work on our assembly lines in the future.”

The virtual simulation is impressively comprehensive, encompassing a complete line section with 41 operating cycles, covering over 1,000 square metres of assembly space. This level of detail allows for the development of effective cycle specifications and health-friendly ergonomic analyses long before the physical production line is built.

Beyond planning, this VR technology serves as a powerful training and information tool. Employees can use VR goggles to explore their future workplace virtually, examining details up close and even practising specific operating cycles alongside virtual „colleagues.“ This advanced preparation aims to shorten the learning phase when employees transition to the actual assembly line.

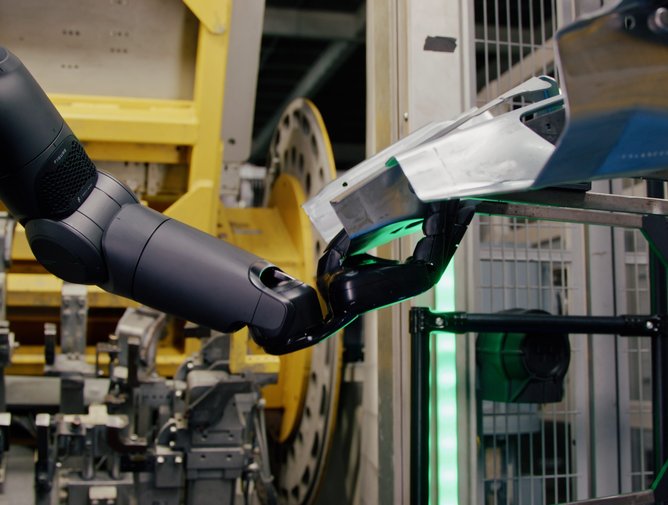

Advanced robotics push the boundaries of automation, improving efficiency and worker safety

Humanoid robots: The next frontier in automation

While virtual reality is reshaping planning and training, BMW is also exploring the physical frontier of automation with humanoid robots. At BMW Group Plant Spartanburg, the company recently conducted a trial run with Figure 02, an advanced humanoid robot from California-based company Figure.

During the several-week trial, Figure 02 successfully inserted sheet metal parts into specific fixtures, which were then assembled as part of the chassis. This task requires particular dexterity, showcasing the robot’s advanced capabilities.

Milan Nedeljković, Member of the Board of Management for Production at BMW AG says: “The developments in the field of robotics are very promising. With an early test operation, we are now determining possible applications for humanoid robots in production. We want to accompany this technology from development to industrialization.”

Figure 02 represents the cutting edge of robotics technology. Brett Adcock, Founder and CEO of Figure, describes it as “the world’s most advanced humanoid robot currently available on the market.” The robot boasts impressive features, including three times the processing power of its predecessor, improved voice communication, enhanced sensors, and fourth-generation human-scale hands with 16 degrees of freedom per hand and human-equivalent strength.

What sets Figure 02 apart is its combination of two-legged mobility and advanced dexterity. This makes it ideally suited for use in areas with physically demanding, unsafe, or repetitive processes, potentially improving ergonomics and safety for human workers.

The BMW iFACTORY: A vision for the future

These implementations of virtual reality and robotics are part of BMW’s broader iFACTORY vision for the production of the future. This strategy focuses on efficiency, digitalisation, and sustainability, constantly seeking new technologies to enhance manufacturing processes.

The use of digital twins and virtual simulations, powered by platforms like NVIDIA Omniverse Enterprise, allows BMW to validate and optimise complex manufacturing systems throughout its production network. This digital-first approach accelerates planning, reduces effort, and aims to realise more efficient, stable vehicle launches in the future.

While BMW’s advancements in Industry 4.0 technologies are impressive, the company is taking a measured approach to implementation. For instance, there are currently no Figure AI robots permanently stationed at BMW Group Plant Spartanburg, and no definite timetable has been established for bringing these robots to the plant.

This cautious approach reflects the challenges inherent in implementing such advanced technologies. Issues such as integration with existing systems, worker adaptation, and safety considerations must be carefully addressed.

However, the potential benefits are clear. From more efficient planning and training through virtual reality to the possibility of robots taking on physically demanding or repetitive tasks, these technologies have the potential to significantly enhance BMW’s manufacturing capabilities.

As BMW continues to explore and implement these Industry 4.0 technologies, it is setting a benchmark for the automotive industry and manufacturing as a whole. By embracing virtual reality, advanced robotics, and digital twin technology, BMW is not just preparing for the future of manufacturing – it’s actively shaping it.

The journey towards fully realised smart manufacturing is ongoing, with each technological advancement bringing new possibilities and challenges. As we stand on the brink of this new industrial era, BMW’s initiatives demonstrate how the automotive industry can lead the way in adopting and benefiting from Industry 4.0 technologies.

Plant Director Armin Ebner sums up the transformative potential of these technologies: “The project is a further step towards the digital and intelligently connected BMW iFACTORY. Virtualisation, AI and data science are accelerating and refining our planning. Digital factory planning enables us to reduce planning effort and realise more efficient, stable vehicle launches in the future.” As BMW continues to push the boundaries of what’s possible in automotive manufacturing, it’s clear that the future of Industry 4.0 is not just a concept, but a reality taking shape on factory floors today.

Quelle:

https://technologymagazine.com/articles/bmw-industry-4-0-revolutionising-automotive-manufacturing

Foto: Humanoid robots are transforming manufacturing by automating complex tasks with precision